1. High-purity semiconductor manufacturing

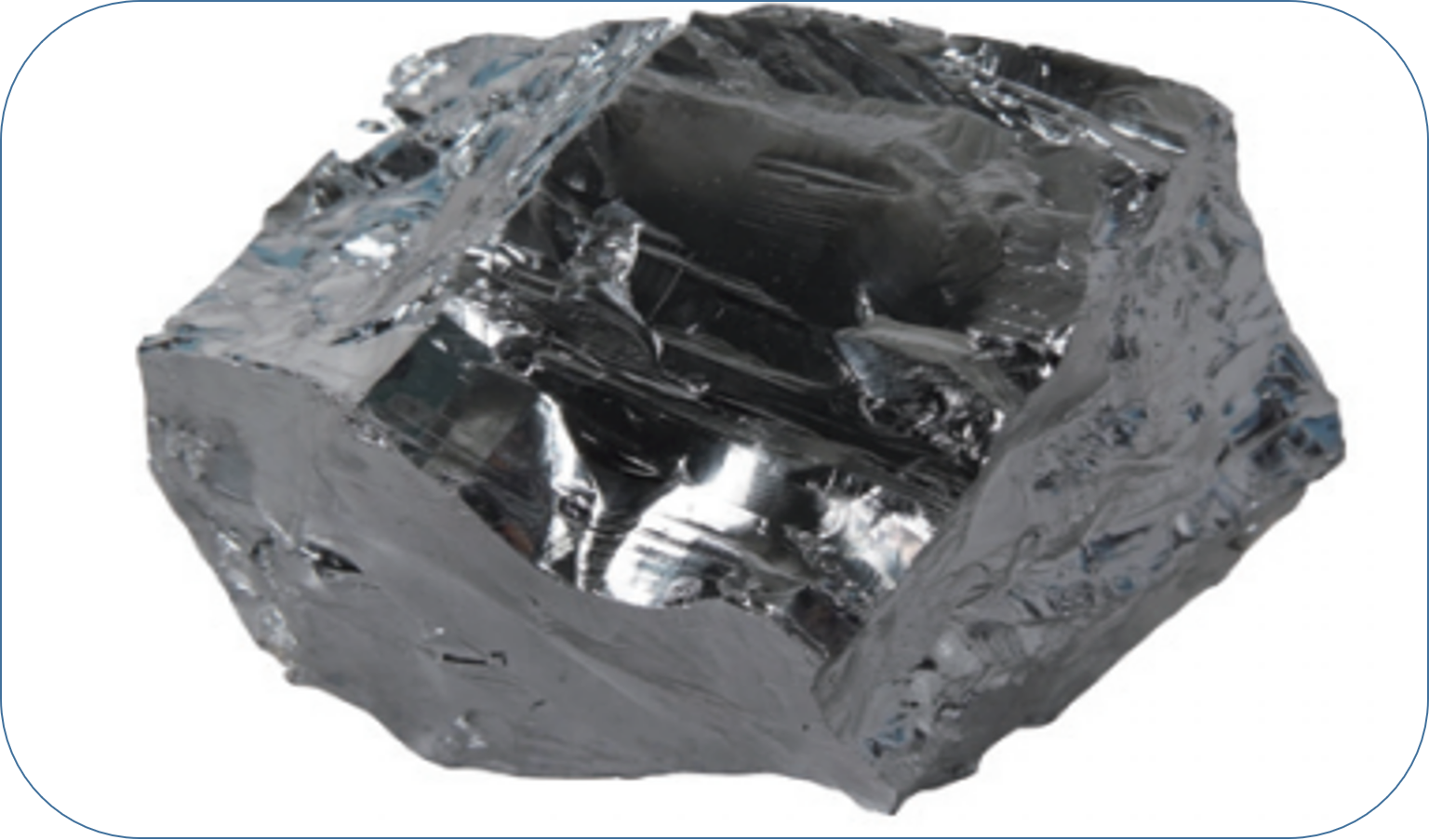

Due to the high melting point, thermal stability, rich resources and the improving technology of making high purity silicon, Silicon integrated circuits and large-scale integrated circuits have been applied to various areas and its consumption is increasing.

2. Silicone industry

Silicon powder is the basis of synthetic materials and used in the production of Silicone rubber, Silicone resin, Silicone oil to enhance their high temperature, electrical insulation, corrosion-resistant, waterproof etc.

3. Refractory industry

Silicon powder acts as antioxidant additive, such as iron groove and iron ditch of Iron smelting, mud water cannon, and containing silicon carbide castable ramming mixes to raise the temperature, resistant to wear and oxidation resistance.

4. Metallurgical and foundry industry

Silicon powder is acting as non-iron-based additives, silicon steel alloy agent to enhance the harden ability of steel. Silicon powder can also be applied to certain metal reducing agent, such as a new type of ceramic alloy.

5. Solar Grade Silicon

Polycrystalline silicon, also called polysilicon, is a material consisting of small silicon crystals. It differs from single-crystal silicon, used for electronics and solar cells, and from amorphous silicon, used for thin film devices and solar cells.